eXtensions - Tuesday 9 September 2025

By Graham K. Rogers

![]()

With the expansion of railways systems in Thailand - metro and mainline - a unit was set up at Mahidol Engineering to teach the skills necessary for railway engineers and management. Early use was made of simulations, but a decision was made, fully supported by the University, to build a sophisticated model track layout for teaching, demonstration, testing and research.

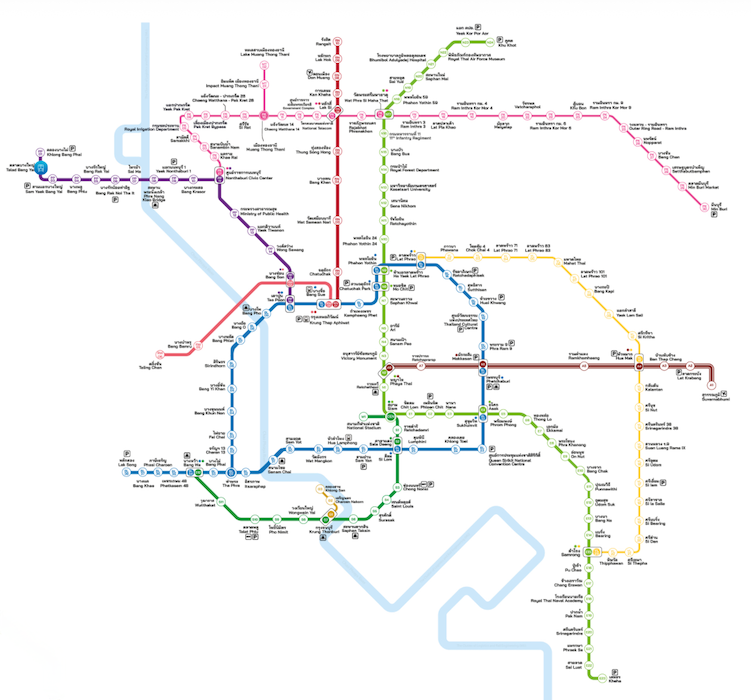

Soon after plans for the original Green Line commuter system were laid down, ideas began to form for two other lines: the MRT from Hualompong Station to Chatuchak; and the Airport Rail Link, eventually from Phayathai on the Green Line, to Suvarnhabummi Airport. As these lines began construction, plans for a far wider Bangkok metro system were put forward. There has been considerable development since that time and more lines are expected to be constructed.

It was with this in mind that a team at the Faculty of Engineering, Mahidol University, began to develop the idea for the Cluster of Logistics and Railway Engineering (CLARE): a specialized group of academics drawn from the Computer, Civil, Electrical, Industrial, and Mechanical Engineering departments, with expertise in the skills needed for railway engineering. CLARE would be developed as a research and teaching unit, under the aegis of, but separate from the Industrial Engineering Department.

The early goals of CLARE were met, with much research work on how railways operate and run, as well as expanded Masters and Doctoral degree programs. One important area of research, that is also taught to the students, centers on signaling, an area that ensures the smooth and safe running of any rail system.

|

|

Theoretical study, including programmed simulation, works up to a point, while visits to railway lines in Thailand and other countries (including Germany, Switzerland, and China) gives students and the researchers wider practical experience. It was recognized, however, that a more hands-on, in-house experience, by way of modeling would be of benefit to demonstrate live runs, with blocking, signaling and track-switching. Initially, modest plans were set in motion.

|

|

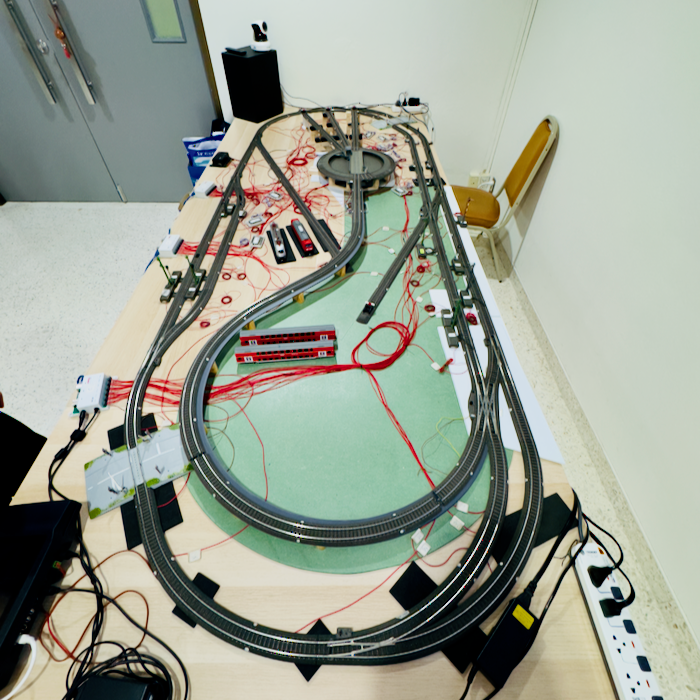

The first layout was developed by a group of electrical engineering students under the guidance of Dr. Thamvarit Singhavilai. With its simple track layout of an oval plus siding, the emphasis was on demonstrating signaling and block control. The signals and much of the trackside furniture were produced using an in-house 3D printer. Despite its simplicity, the concept succeeded and was shown to have potential for expansion.

The obvious limitations of this basic track layout, along with the ways that students were able to see live demonstrations of signals and controls without the need for study trips, spurred the teaching staff to push for an expanded system: a more sophisticated layout, within a limited budget, that would allow more complex operations with several trains. The layout included double track sections, points and crossings, sidings and even a turntable. I was reminded of the one I had seen at the Didcot railway museum. While these used to be common in the days of steam, there are few working examples now.

|

|

This upgraded system took over a year to design and construct. As befits such a project that involves different types of engineering skills, much effort was taken over the design of the electrical system and the wiring, which was left exposed for ease of access. As with the first track layout, some of the accessories were 3D printed at the Faculty. This had three benefits: reduced expenses, time, and it presented opportunities for related undergraduate student projects, leading to future in-house production.

The second, slightly bigger system was designed and built by CLARE staff. At the time, it was recognized that a larger layout would have more value in teaching and would provide improved research possibilities. As Dr Waressara Weerarat had already visited similar model track installations at TU Dresden and TU Berlin, a firm idea of what was needed had already been formed. The project was signed off by the VP of the University who recognized its long-term value. This included the electronics and signaling, the Märklin track and models, multiple television screens for demonstration purposes, and a building on the roof of the Faculty of Engineering to house the entire system.

That building has two main parts. On entering, a visitor is faced with a video wall. This is made up of 18 plasma TV screens, giving a total screen area of approximately 8m x 2m. The display can be used as a single large screen, or information can be shown using several permutations, down to 18 separate screens. The screen wall faces a bank of seats for an audience of up to 48 (plus standing room) for lectures or events, such as a recent visit by a group from the Ministry of Higher Education.

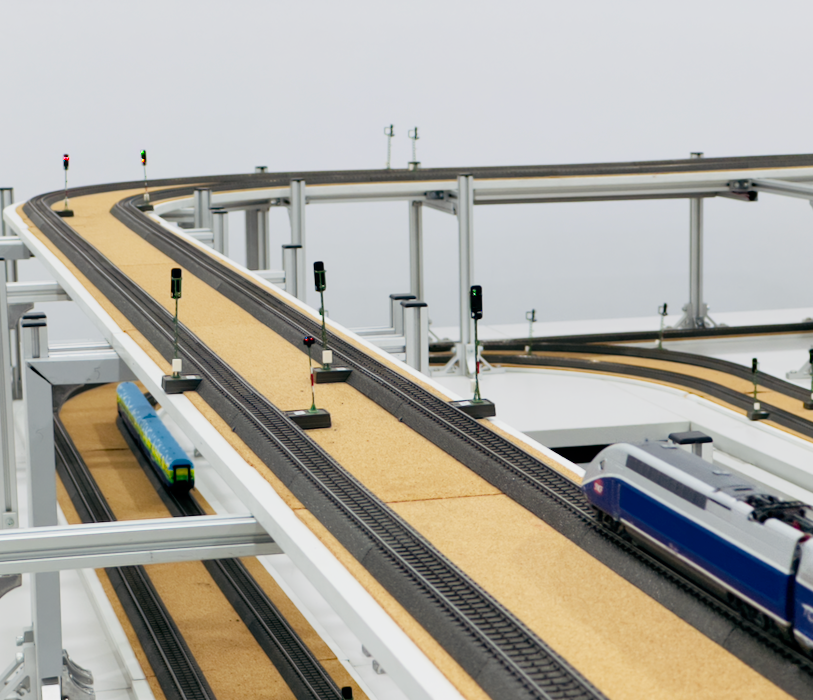

A separate room houses the track layout. The model train system takes up some 9m x 3m of the space, but there are other connected systems along with a maintenance area to the side. As is typical of such designs, the track is circular. Main line systems are point to point, which is impossible to create with a system in a room with limited space. The HO gauge tracks, including points, crossovers, elevated sections and sidings are set up so the track blocks and related signaling are as realistic as possible. As on a full size railway system, it is impossible to run two trains on the same section (or block) of track.

Signals indicate whether a block is free or not with green or red signals respectively. The same block and signaling rules apply when a train is scheduled to switch tracks or use a crossover. All other trains are prevented from using that block until the train has cleared the section. Power to the trains is provided by a third rail, but the Märklin track design makes this almost invisible.

|

|

|

|

The installation is raised on trestles, and easy access is provided so staff may effect any changes needed or carry out maintenance, without the need to stop all trains or cut off power to all sections of track. Unlike the two previous systems, wiring is installed beneath the installation. Controls and connections are designed for easy access.

|

|

There are also computers with several monitors to one side of the room that connect to the track system and are used for SCADA (supervisory control and data acquisition) to feed traction power and station infrastructure. The data collected here is invaluable to help in the design future real-life installations.

Currently several modules are taught currently using the track layout with others planned. These include:

|

|

CLARE has developed relationships with several major players in the industry and other academic institutions with rail system programs. These include the Red Line commuter system; Alstom; Bangkok Mass Transit System (BTS - Green Line); Mass Rapid Transit (Blue Line metro); and Technische Universität Braunschweig", Germany.

With the complexity of the rail industry, CLARE - the railway engineering section of the Faculty - is perfectly positioned with its expertise in system engineering and system integration. The department oversees the life cycle of a railway, from planning, installation, operations, and maintenance. The Operations and SCADA facilities of the track installation lab are examples of the initiative at Mahidol Engineering.

Although this track layout system is primarily used for teaching and research, with the full width monitors it is an impressive demonstration tool that has been used to good effect in outlining the expertise that Mahidol Engineering has to offer. A future plan is to introduce new graduates who have been accepted for employment by companies in railway engineering fields to a range of railway systems, so they may be of more value to their future employers. It is also planned to offer the use of these facilities to outside companies and organizations so they may bring their staff to learn more about live signaling operations.

Photos of Dr Thamvarit Singhavilai, Electrical Engineering Students and Dr Phattanard Phattanasri provided by CLARE.

Graham K. Rogers teaches at the Faculty of Engineering, Mahidol University in Thailand. He wrote in the Bangkok Post, Database supplement on IT subjects. For the last seven years of Database he wrote a column on Apple and Macs. After 3 years writing a column in the Life supplement, he is now no longer associated with the Bangkok Post. He can be followed on X (@extensions_th). The RSS feed for the articles is http://www.extensions.in.th/ext_link.xml - copy and paste into your feed reader. No AI was used in writing this item.

For further information, e-mail to

Back to

eXtensions

Back to

Home Page